Check out Dry Moly Spray online for use in various machine maintenance activities

If you were to check out the traditional lubricants that were used to keep machinery in proper working conditions, they are the typical grease and oil varieties. However, they do not suffice the needs for lubrication in today’s machines, which are large, complex, have many internal parts, and work at high speeds. In such machines, you need to use a dry lubricant such as molybdenum disulfide, which is capable of withstanding the high temperature and pressure of this environment and still providing effective lubrication. It is an inorganic compound, and its formula is MoS2.

Buy Dry Moly Spray Online As An Alternative To Liquid Lubricants

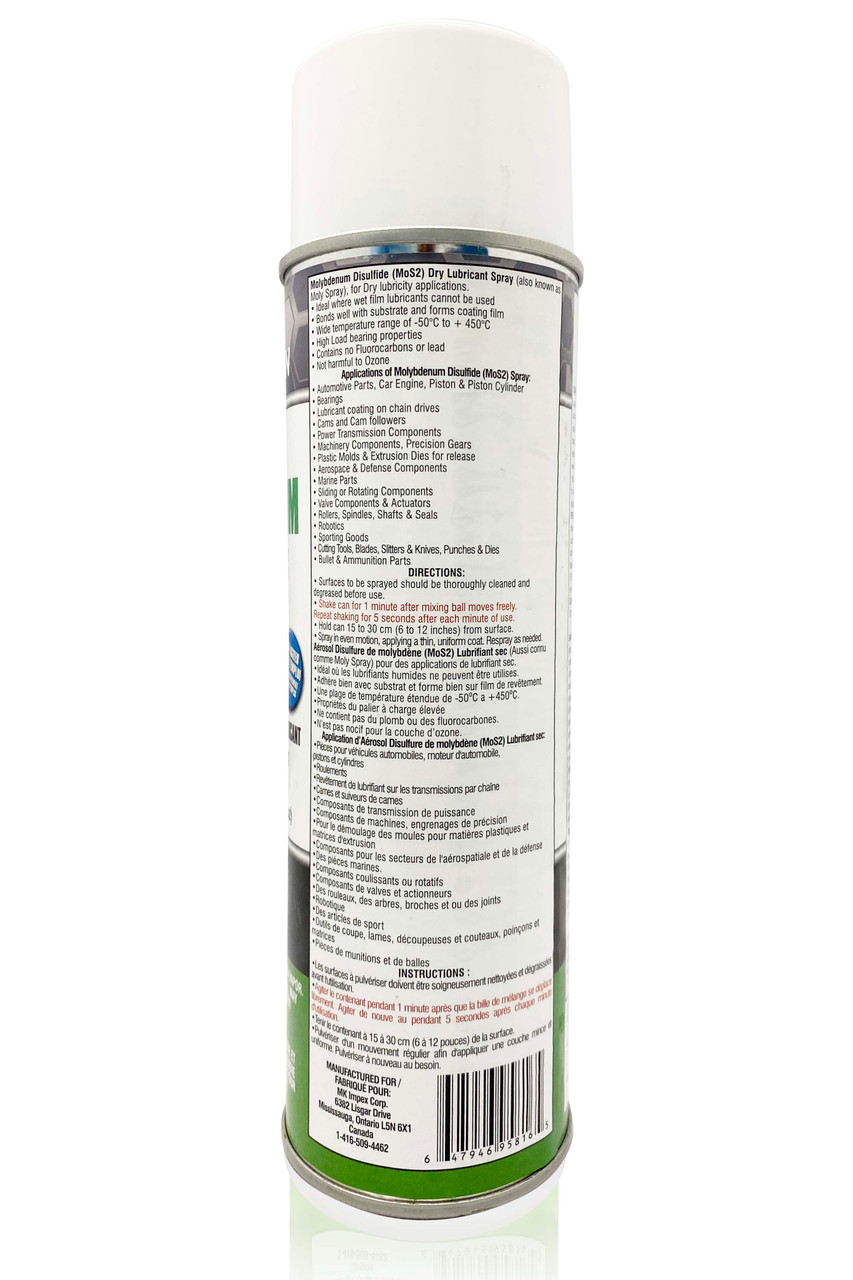

When selecting a dry lubricant, you need to check if it has a really low coefficient of friction. In this contact, molybdenum disulfide satisfies, so it is able to make moving metal parts easily slide against one another. It can be applied to various types of metal surfaces, which shows its ability to adjust to different surfaces. You can apply it easily by spraying, after which it will become a coating that binds strongly and protects the surface from not just frictional wear but also rusting.

It is the easy film-forming nature of molybdenum disulfide that makes it so preferred. Once applied, its film provides the needed protection for metal parts of a machine to slide easily. As a result, the machine performs faster, uses less energy, and gives a higher output per day. This lubricant is very effective in bringing down maintenance costs and efforts, keeping some of the most heavy-duty and high-speed machines in pristine working condition.

If you have been searching for a dry lubricant that works well even in a vacuum environment, molybdenum disulfide should be selected. It is capable of functioning in such an environment and is used in place of graphite in such situations. Buy dry Moly Spray online, as you can get it at the lowest prices for various lubrication needs. Out of the many dry lubricants available, it is a very popular one as it shows desired results in usage time and again.

One of the most interesting aspects of molybdenum disulfide is that it does not react with diluted acids. It is suitable for applying to machines that deal with such acids during the production process, as it will not react to them and carry out lubrication effectively. In an oxidizing environment, it is capable of resisting temperatures as high as 350 degrees Celsius. It can be easily mixed into a variety of oils, wherein it enhances their lubricity properties and makes them more powerful by infusing a lower coefficient of friction into them.