How To Utilize The Dry Moly Spray In Different Purposes?

Dry Moly Spray | images. cdn11.bigcommerce.com

The Dry Moly Spray is nothing but the Molybdenum Disulfide in the aerosol form. It is perfect for some specific components where the use of wet lubricants is not appropriate. Moreover, such a brilliant substance can resist high loads and extreme pressures. You can also avoid galling or early pick-up by utilizing Dry Moly Spray.

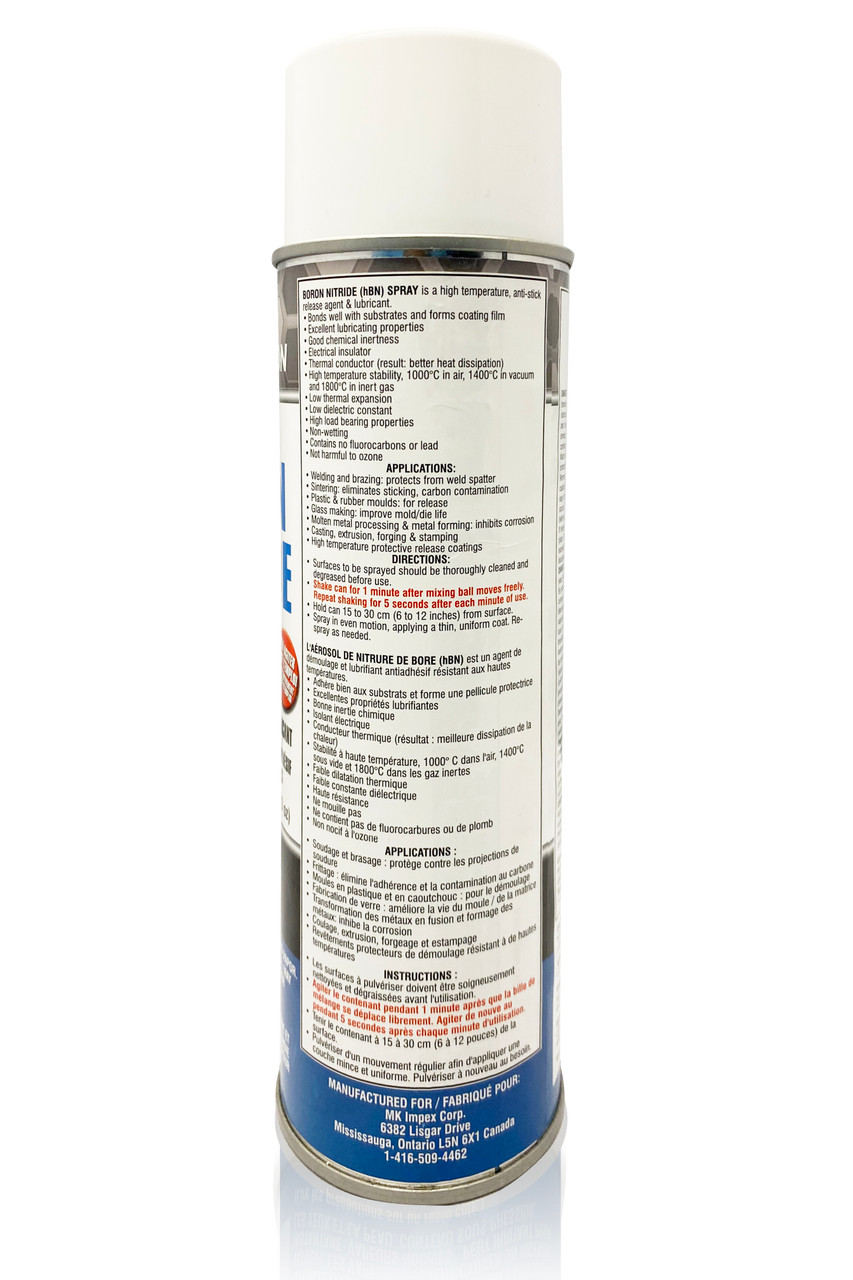

Such a material comes in specially packed aerosol cans. You can even recycle such cans and protect the environment in the process. This lubricant will dry up quickly and thus does not make the surface sticky in any respect. Furthermore, the application is very convenient and does not require too much attention.

More Details About The Characteristics

The sprayis specially designed for platforms that do not tolerate wet lubricants. For smooth penetration, you can apply this spray in a wet form. Within a time frame of two or three minutes, you will observe a great change. The quick-dry technology will let the wetness disappear instantly. There will only be a thin protective film of MOS2. The approximate percentage of the metal will be 70.

The main intention of the Dry Spray is to increase the life of a particular tool or machine. Additionally, reduced friction is also one of the characteristics of the substance. It is more applicable for sliding surfaces. Some instances include;-

Pins

Plain bearings

Cams and Rollers

Slides

Furnaces

Ovens

Chains

Extrusions

Drawings

Jet Engines

Conveyors

Kilns

To enhance the productivity and longevity of some components or assemblies, you can use a combination of a wet lubricant along with the Dry Moly Spray. Along with the excellent spray, you can also get the MOS2 coating in fluid and paste forms.

For exotic alloys, this lubricant is really useful. Moreover, for being an aerosol substance, it can be a fantastic alternative for the gasket coating. Additionally, it can function as an anti-seizing agent under specific temperatures.

The metal-forming lubricant can give shape to sturdy machines with high productivity. Buy the products are only from registered sources.