The Benefits Of Solid Film Lubricants

Solid Film Lubricants | cdn11.bigcommerce.com

The existing conditions of lubrication as the viscous metric features of the lubricant are formulated by the base oil. The moment you go on to segregate the surface of the machines in a relative motion a degree of thickness is formulated. In a major chunk of mechanical interactions, there is bound to be a boundary condition. In a few cases, the surface may be on the cloud if the relative speed is not high it would go on to formulate a degree of thickness.

Now in such cases, friction additives and wear control are going to impart film strength for a varied form of protection that is going to exist at a surface level. The best part about solid film lubricants is that it goes on to include chemical additives.

In-depth analysis of solid film lubricants

If you figure out that the loads are on the higher side, where is the relative motion of the sliding surface? The major benefit of solid film lubricants is that it is known to provide an extra layer of protection. If you figure out that there is a low start-up of fiction when it comes to mechanical movements, then solid film lubricants are selected. Every solid lubricant is known to work in a unique way of its own.

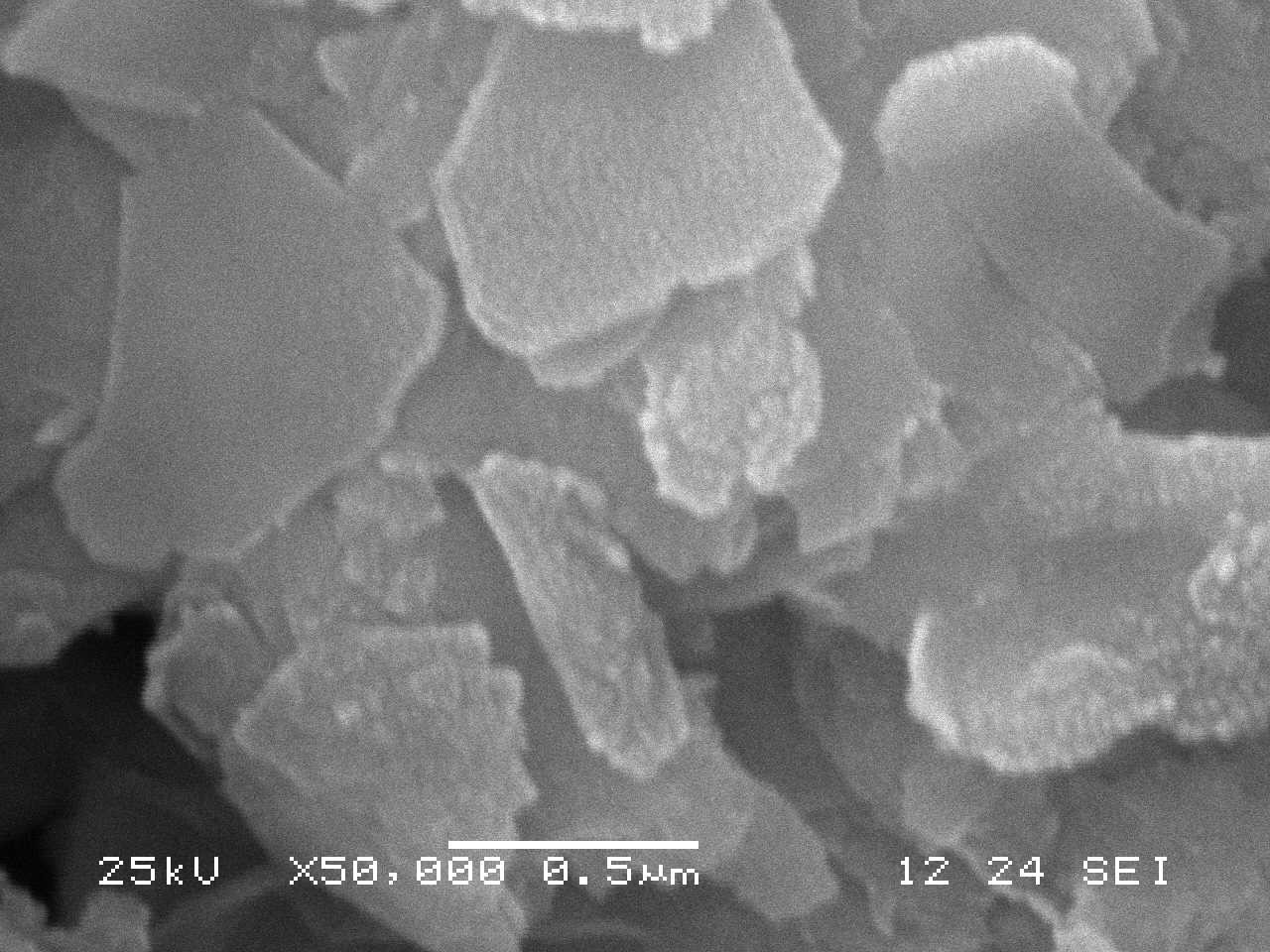

The additives that emerge in the form of graphite or MOS2 are formed from inorganic compounds that are developed from a molecular structure sticking to a particular form of a machined surface. These structures go on to develop layered lattices taking place facilitating slide in an easy manner. These layers are incorporated from strong molecular bonds and in between the layers there exist weak Waal Forces that pave the module for slip panes.

There are factors in the form of temperature or water vapour which have a major role to play. When you are using a solid film lubricant it is known to reduce the frictional interaction that is present on the machine surface and goes on to encourage relative motion. It emerges at the slip plane when it relates to an additive structure. Various other forms of solid film lubricants are there like PTFE and borate. You may refer to one of them as Teflon which is going to be resistant to a low coefficient of fiction.

When it comes to the formulation of a liquid lubricant solid lubricants have a role to play. A few of them are known to be working in the form of a dry film lubricant. If you find that the formation occurs along with a liquid lubricant then the concentration levels with a solid film lubricant has to be implemented in a proper way.