Judging the Effectiveness and Applicable Features of WS2 Dry Lube

Features of WS2 Dry Lube | cdn11.bigcommerce.com

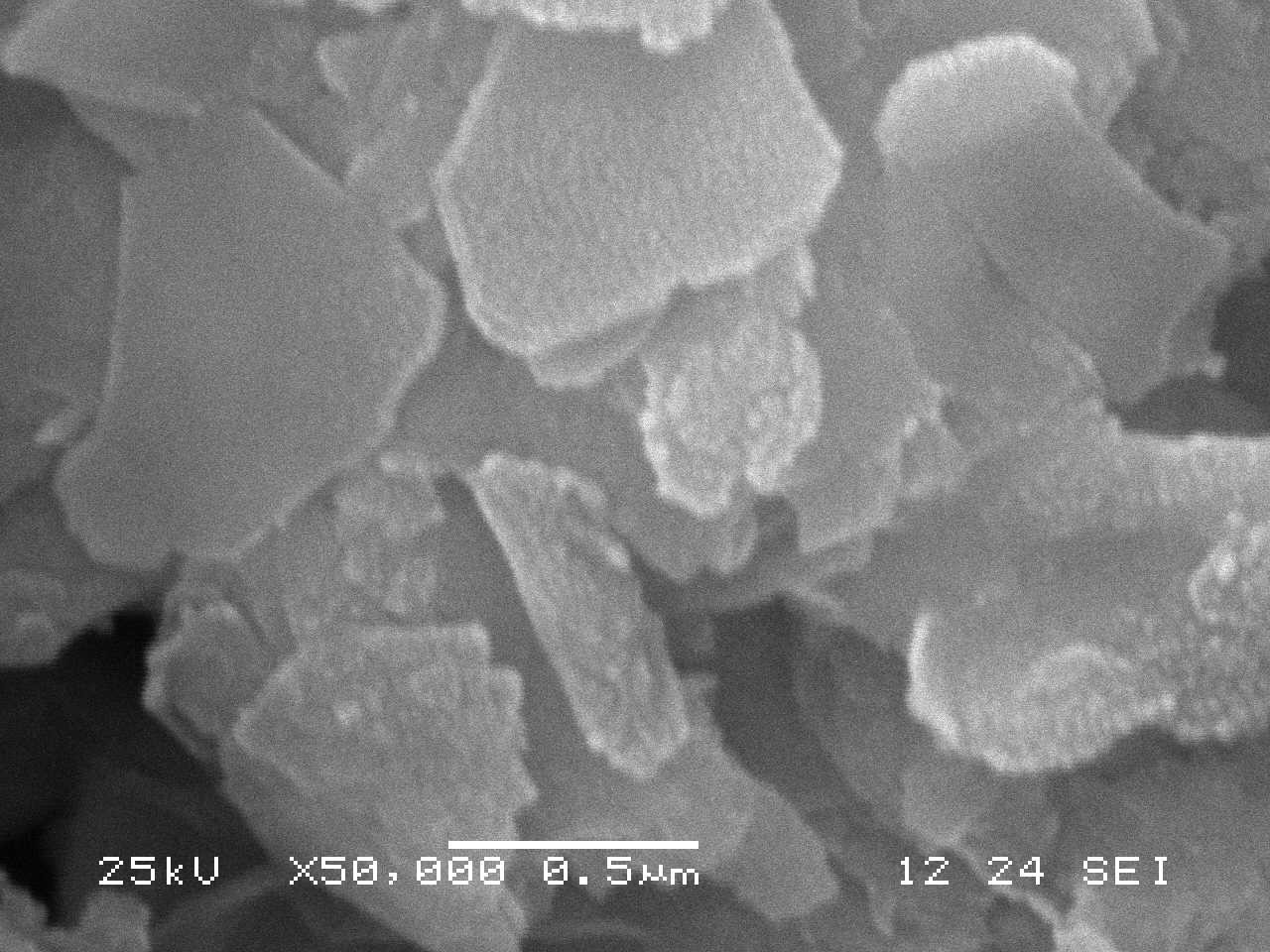

It is a Tungsten Disulfide that comes with the common name WS2. It is the most popular and the kind of low-friction dry coating that is used in conjunction with pressurized air. It helps in impinging the kind of dry and metallic coating without the use of heat, adhesive, or the kind of binders. This kind of coating can sit well on the surface without extra effort. It can well stick to the resin or the metal with the ideal thickness of 0.00002″ (1/2 micron). The kind of WS2 coating can cause a performance improvement. There is an enhancement of the service tenure of the various fasteners.

Consistent Features of WS2 Dry Lube

You can check the Features of WS2 Dry Lube. Here is the ideal lubricant that helps in reducing the level of friction and unnecessary noise and commotion. It is something that can help improve the quality of mold release. It is highly effective in solving extreme wear issues and even causes a stoppage in all ill processes of seizing, fretting, and galling. The dry lube comes in a combination color of blue or dry. The coating can work in conditions of dry temperature. It will make sealing possible and easy in all weather conditions.

Steps of Coating Application

Here you can learn the application process of the coating. First, it is necessary to check the available parts and clean them well to remove traces of dust, grease, and the rest of the components. Then there is the stage when the coating should be pre-treated by making use of rasping surface blasting. The application of WS2 is done innovatively using high-speed impingement with the use of the application and the specialized tool. It is time then when the parts should be cleaned ultrasonically to remove and clean the unbounded coating. In the last stage, it is necessary to inspect to make sure the proper coating application is done before the final packaging.

Benefits of WS2 Coating

The Features of WS2 Dry Lube are obvious. It is also important to consider the obvious traits and benefits of the WS2 coating. The coating is used because of its low friction. This helps in improving the action and also helps in extending the span of the coated fastener. It helps in galling and fretting and even the friction that can be caused by dissimilar metals and their level of hardness. The WS2 is known for its complete lubricity through the complete texture.

The WS2 coating can innovatively and molecularly stick to the material to which it is applied. The coating will help in maintaining dimensional veracity in the case of the fastener. To be precise the WS2 coating is applied without the necessity of heat curing.